Products >> Carbon Anodes >> Baked Carbon Anode

Pre-Baked Anodes for Electrolytic Aluminum Production

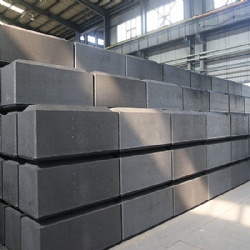

Baked Carbon Anodes

Shanchun® Carbon – China’s leading Carbon Anode supplier. whatsapp +8615731101397 !

Pre-baked anode for aluminium electrolysis

Pre-baked carbon anodes are in a leading position of the aluminum industry. The main function of the pre-baked anode is to introduce electricity current into the electrolytic cell during the aluminum electrolysis process and participate in the electrochemical reaction.

Shanchun® Carbon mainly supply pre-baked anodes for electrolytic aluminum. The products have various sizes, among them, 1450mm and 1500mm pre-baked anode blocks are widely used in major aluminum smelters. One of our company's products, slotted anodes, is a new energy-saving and power-saving carbon product, which is popular with users at home and abroad. Its production process and product performance are also advanced in the world.

Prebaked Carbon Anode is made from raw materials such as petroleum coke and coal tar pitch, and then processed by mixing, extruding, high-temperature baking and other processes. It is used as a conductive anode in the electrolytic cell of primary aluminum smelter aluminum. Baked anode has the characteristics of low ash content, low sulfur content, good plasticity and high strength.

Physical and Chemical Specifications

Mainly 1450*660*540, and can also be processed according to customer drawings.

|

Item |

Unit |

Guarantee Value |

Typical Value |

|

|

Apparent Density |

G/cm3 |

1.56(Min) |

1.56 to 1.60 |

|

|

Electrical Resistivity |

Microohm-mu |

56(Max) |

52.0-56.0 |

|

|

Real Density |

G/cm3 |

2.06(Min) |

2.06-2.10 |

|

|

Compress strength |

Mpa |

38(Min) |

38-45 |

|

|

CO2 reactivity |

Residue |

% |

91(Min) |

91-95 |

|

Ash |

% |

2.5(max) |

1.0-2.5 |

|

|

Air Reactivity |

Residue |

% |

92(Min) |

93-97.5 |

|

Ash |

% |

2) |

0.1-2.0 |

|

|

Thermal Conductivity |

W/mk |

3.0(Min) |

3.0-4.5 |

|

|

Flexural Strength |

Mpa |

9.0(Min) |

9.0-13.0 |

|

|

Permeability |

NPm |

2.3(Max) |

0.5-2.3 |

|

|

Thermal Exposure |

k-1 |

4.0*10-6(Max) |

3.0-4.0 |

|

|

Ash |

% |

0.3(max) |

0.5-2.3 |

|

|

Fe |

ppm |

374(max) |

580-374 |

|

|

Si |

ppm |

275(max) |

540-275 |

|

|

S |

% |

1.2(max) |

1.0-1.2 |

|

|

Ni |

ppm |

250(max) |

250-182 |

|

|

V |

ppm |

150(max) |

69-150 |

|

|

Na |

ppm |

100(max) |

42-100 |

|

Advantages

1. High antioxidant

2. High thermal shock resistance

Coefficient of thermal expansion< 4×10

Thermal conductivity < 3 W/mk

3. High current density

The current density >0.8A/cm2

4. Low electrical resistance

Electrical Resistivity : 55-56μΩm

Application

Products Category

Contact Us

Tel: +86 13184770996

E-mail: [email protected]

Whatsapp: +86 13184770996

Add: Recycling Chemical Industry Park,Shilian District,Shijiazhuang, Hebei, China 052160