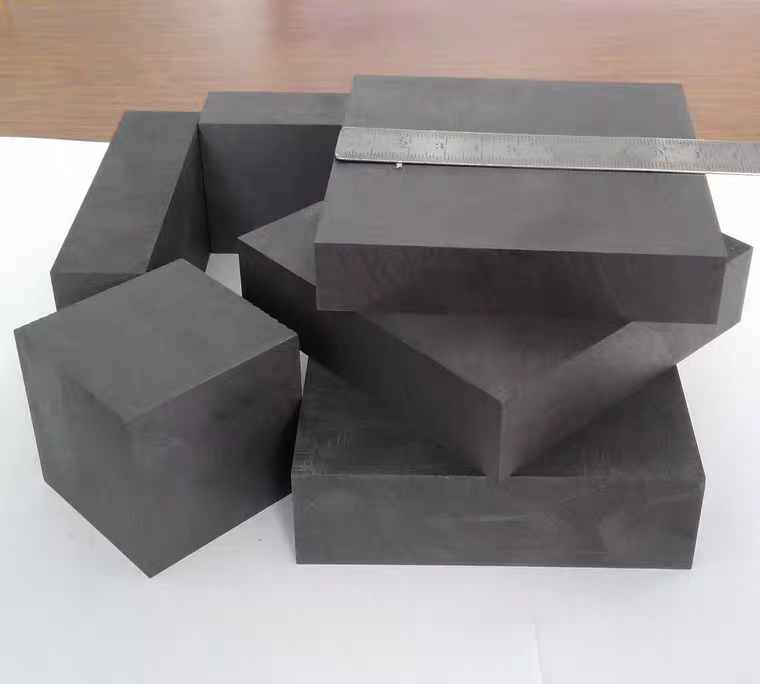

Products >> Graphite Products >> Graphite Block

Molded Graphite Block

Shanchun® graphite block – Custom Graphite products specialist,whatsapp +8613184770996!

Shanchun® supply various grades and sizes of graphite and carbon in block form. Made from petroleum coke, graphite blocks are widely used in metallurgy, machinery, electronics and chemical industry, etc. Our graphite products are available in isostatic graphite, fine grain graphite, medium grain graphite, high pure graphite and kinds of domestic and imported graphite.

Technical Specification of Graphite Material

|

Type |

Bulk Density (g/cm3) |

Resistivity μΩ.m |

Thermal conductivity W/(m) |

Thermal expansion coefficient (x10-6/℃) |

Shore Hardness HSD |

Flexural strength Mpa |

Compressive strength Mpa |

Porosity %≤ |

Granularity μm |

|

Moled Graphite |

1.8 |

8-11 |

125 |

5.46 |

45 |

43 |

75 |

17 |

13-15 |

|

1.85 |

8-10 |

142 |

4.75 |

48 |

46 |

90 |

13 |

13-15 |

|

|

Isostatic Graphite |

1.9 |

8-9 |

140 |

5.1 |

58 |

59 |

98 |

11 |

8-10 |

|

1.95 |

11-13 |

87 |

5.64 |

76 |

68 |

145 |

11 |

8-10 |

|

|

1.68 |

13 |

- |

- |

- |

25 |

50 |

- |

- |

|

|

1.82 |

14.2 |

- |

- |

68 |

58 |

118 |

12 |

- |

|

|

1.85 |

13.5 |

- |

- |

67 |

65 |

135 |

11 |

- |

|

|

Coarse grain |

1.6 |

9-12 |

- |

- |

≥25 |

≥13 |

≥22 |

- |

0-2 0.8 |

|

Fine grain |

1.72 |

8-11 |

- |

- |

≥30 |

≥17 |

≥30 |

- |

0-2 0.8 |

|

Size available (mm) |

|||||

|

400*400*2100 |

500*400*1900 |

500*500*1900 |

650*400*1900 |

700*350*1900 |

740*400*2200 |

|

830*400*2100 |

810*410*2200 |

φ600 x 360 |

φ700 x 360 |

φ800 x 360 |

φ900 x 360 |

|

φ1000 x 360 |

φ1100 x 360 |

φ1200 x 360 |

φ1300 x 360 |

φ1400 x 360 |

φ1500 x 360 |

Application

Main types of graphite blocks are such as vibrated molding graphite blocks, molded graphite blocks and isostatic graphite blocks. They are widely used in various occasions as below.

Producing graphite crucible, moulds, rotor and shaft etc.

Lining materials for the furnaces

Hear exchangers

Various machining parts in acid, alkaline and corrosion environment

Manufacture seals and bearings in pumps, motors and turbines

Boats and Trays for Sintering

Other solar, foundry, chemicals, electronics, ferrous metals, high-temp. processing, ceramics and refractory.,etc.

Advantages

Low electric resistance

Good electric and thermal conductivity

Good physical and chemical performance

Strong thermal shock resistance ability

High quality, Low cost & easy machining

High melting point

High temperature resistance

High anti-deformation ability

Products Category

Contact Us

Tel: +86 13184770996

E-mail: [email protected]

Whatsapp: +86 13184770996

Add: Recycling Chemical Industry Park,Shilian District,Shijiazhuang, Hebei, China 052160